-40%

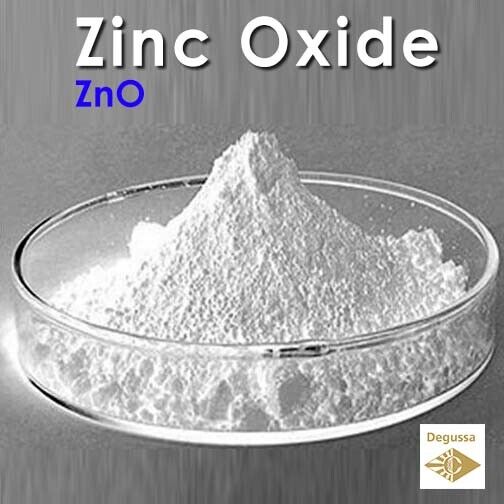

Zinc oxide - Calamine, Philosopher's wool, Chinese white Flowers of zinc pottery

$ 1.89

- Description

- Size Guide

Description

Zinc oxideTake a look at other Materials for Ceramics!

- Effect Glazes

- Pigments (stains)

- Colour Glazes

- Underglazes

- Lustres (lusters)

- Gold, Platinum, Silver

- Colourless Glazes

- Frits, Tools, Oxides, Engobes and Thinners

Formula:

ZnO

Material Name:

Zinc(II) Oxide - powder

Topological Polar Surface Area

:

17.1 Ų

Complexity

:

2

Density

:

5.606

g/cm

3

Molar mass

:

81.406

g/mol

Description

Visit the site

ceramic-glazes.com

for more information.

Zinc oxide is an inorganic compound with the formula ZnO. ZnO is a white powder that is insoluble in water. It is used as an additive in numerous materials and products including cosmetics, food supplements, rubbers, plastics, ceramics, glass, cement, lubricants,[10] paints, ointments, adhesives, sealants, pigments, foods, batteries, ferrites, fire retardants, and first-aid tapes. Although it occurs naturally as the mineral zincite, most zinc oxide is produced synthetically.

The applications of zinc oxide powder are numerous, and the principal ones are summarized below. Most applications exploit the reactivity of the oxide as a precursor to other zinc compounds. For material science applications, zinc oxide has high refractive index, high thermal conductivity, binding, antibacterial and UV-protection properties. Consequently, it is added into materials and products including plastics, ceramics, glass, cement,[58] rubber, lubricants,[10] paints, ointments, adhesive, sealants, concrete manufacturing, pigments, foods, batteries, ferrites, fire retardants, etc.

Uses in Pottery

Zinc white is used as a pigment in paints and is more opaque than lithopone, but less opaque than titanium dioxide. It is also used in coatings for paper. Chinese white is a special grade of zinc white used in artists' pigments.

Ceramic industry consumes a significant amount of zinc oxide, in particular in ceramic glaze and frit compositions. The relatively high heat capacity, thermal conductivity and high temperature stability of ZnO coupled with a comparatively low coefficient of expansion are desirable properties in the production of ceramics. ZnO affects the melting point and optical properties of the glazes, enamels, and ceramic formulations. Zinc oxide as a low expansion, secondary flux improves the elasticity of glazes by reducing the change in viscosity as a function of temperature and helps prevent crazing and shivering. By substituting ZnO for BaO and PbO, the heat capacity is decreased and the thermal conductivity is increased. Zinc in small amounts improves the development of glossy and brilliant surfaces. However, in moderate to high amounts, it produces matte and crystalline surfaces. With regard to color, zinc has a complicated influence.

Payment and Shipping

You can order another quantity. I always combine the packages. The costs for posting depend of total weight of the package. If you wish to transfer funds via bank account, I have such in UK in GBP, so ask for my bank details

.

No shipping to Argentina, sorry!

Packaging

You'll get the ordered quantity put in a polyethylene bag and labeled with the English name.